process of copper grinding

Metal Blanchard Grinding | Precision Metal Grinding

This process provides high removal rates for fast results. Blanchard grinding does not produce a very fine finish (approximately 64 RMS max surface finish), but as it is generally performed early on in the part production process, surface finish is not usually of high importance. Blanchard Grinding for Parts of All Shapes, Sizes Materials

copper mining process grinding

grinding mining copper grinding mining crusher · crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, cone crusher, . of a crusher in australia. copper ore . Contact Us equipment used in crushing and grinding in the production of copper. Contact Supplier

USA Mineral grinding aids and process of grinding ...

USA US383519A USA USA US A US A US A US 383519 A US383519 A US 383519A US A US A US A US A US A US A Authority US United States Prior art keywords grinding mineral additive amino acids cement Prior art date Legal status (The legal status is an assumption and is .

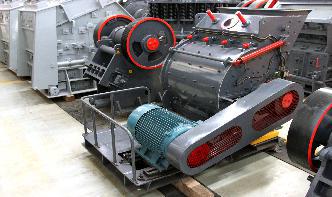

Copper Grinding Machines | Crusher Mills, Cone Crusher ...

Copper ore grinding mill for beneficiation process. SAG mill is a another widely used copper ore grinding machine. SemiAutogenous Grinding mill utilizes steel balls in addition to large rocks for grinding.

grinding process in copper refining

grinding process in copper refining. copper, lead and zinc smelting and refining* copper mining process copper is a get more info. grinding of copper Get Price leave your quotation. cutting tool applications chapter 16: grinding wheels and . jan 27, 2011· grinding or abrasive machining is the process of removing metal from

copper ore crushing process | Ore plant,Benefication ...

Dec 09, 2013· Froth flotation grinding mills,Copper ore ball mill process – Gold . Froth Flotation – Summary For a plete explanation of froth flotation, see the later Froth Flotation section. Froth flotation was the key process in extracting . Copper Ore Flotation Process for copper mining process or copper . Copper ore beneficiation flotation machine.

1 General Albion Process Description

1 General Albion Process Description The Albion Process is a combination of ultrafine grinding and oxidative leaching at atmospheric pressure. The feed to the Albion Process is a concentrate containing base or precious metals, and the Albion Process is used to oxidise the sulphide minerals in the concentrate and liberate these

copper processing | Definition, History, Facts | Britannica

Copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products. In its pure form or as an alloy, copper (Cu) is one of the most important metals in society. The pure metal has a facecentred cubic crystal structure, and ...

Crushing Process For Copper Ore

Crushing Process For Copper Ore. The production process of copper ore mainly include: crushing, grinding, ore dressing. In the crushing process, three crushing circuits are suitable for high hardness iron ore broken, which can complete the ore crushing and partial dissociation work so as to improve the efficiency of the subsequent grinding.

Mining Process For Copper – Series I Xinhai

The main source of copper is sulfide copper and oxide copper. The mining process for copper includes crushing and screening, grinding and flotation, thickening, after these stages, the copper concentrate can get. Here is a brief introduction of the smallscale copper mining process, let us see how to separate copper.

Copper Ore Grinding Process

Copper Ore Grinding Machine, Copper Mining Process Plant. Therefore, copper ore investors should adopt highquality copper ore grinding machine to improve the mining efficiency. In the copper mining process plant, the? chat online; Copper Department of Energy. The most commonly mined type of copper deposit, porphyry copper, is found ..

Primary Copper Smelting

Primary Copper Smelting General1 Copper ore is produced in 13 states. In 1989, Arizona produced 60 percent of the total U. S. ore. Fourteen domestic mines accounted for more than 95 percent of the megagrams (Mg)

Advanced Controller for Grinding Mills: Results from a ...

Process Description The copper concentrator in Pinto Valley, Arizona processes a % grade copper ore from a nearby open pit mine. The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball mills. The concentrate is transported to a smelter a few miles away. The

Copper beneficiation process Yantai Jinpeng Mining ...

Copper ore divides into ore sulfide,ore oxide and mixing ore according to its oxide rate . The main process for copper ore is flotation, for refractory mixed copper ore and refractory oxide ore, normally use hydrometallurgy process .It is a high technological enterprise that integrated research, manufacture, sales and service . The company has multiple subsidiaries such as Mineral ...

What Is Copper Smelting? (with pictures)

Apr 02, 2020· Each copper smelting operation has its own unique process, however many share similar basic steps. A typical process might begin with grinding of the ore into a powder. This powder is processed with chemicals and air to separate out some of the unwanted material and concentrate the copper.

How Mining Works Resolution Copper

Once ore comes out of Resolution Copper's underground mine, it's processed to separate the copper from the rock before it is sent to be smelted and refined into % pure copper – ready to be manufactured into a variety of products. The process works like this: A wet grinding process turns the crushed rock into a fine sand.

Grinding Process Of Copper Agrigent

Al sic copper in properties in grinding process. Al sic copper in properties in grinding process grinding process is an important machining techniqueand it has a wide range of applications in precision machining and ultraprecision machiningthe wheel is a widely using tool in the grinding processbu...

Grinding and Polishing ASM International

Grinding and Polishing / 37 Fig. Automatic grinding and polishing machine Subroutine : Cleaning Ceramographic Mounts After each abrasive step, rinse each specimen in warm tap water. Do not remove specimens from the holder if an automatic polishing machine is being used. Use distilled or deionized water if the tap water is too hard.

Copper FL

Produce copper directly at the mine Rapid Oxidative Leach® (ROL) is another of our innovative about to rock your world. This mechanochemical process can leach 9799% copper directly on site, from concentrates as low as 5% copper in less than six hours.

The oxidation of copper sulfide minerals during grinding ...

A potential explanation of the different response of primary and secondary copper sulfide minerals to bentonite is that bentonite particles may preferentially coat the chalcocite surface during grinding. The oxidation of copper sulfide minerals is an important aspect in mineral processing.

Mill (grinding) Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Copper Mining Process Plant,Crushing Grinding Process

Working Principle of Copper Mining Process Plant. Mining of copper ore, first by the jaw crusher preliminary broken, after the broken to a reasonable fineness via the hoist, the feeder evenly into the ball mill, the ball mill of copper ore crushing, grinding. After grinding ball mill of copper ore fines into the next process: classification.